In the precision-driven world of CNC machining, the selection of the best coolant for CNC machines is critical for maintaining optimal thermal management and tool longevity. Coolants serve not only to dissipate heat generated during machining processes but also to enhance the lubrication of cutting tools, reduce friction, and flush away metal shavings and debris.

With various formulations available, including water-based and oil-based options, understanding the specific requirements of your CNC operations is paramount. Delving into the properties, advantages, and compatibility of different coolant types will uncover essential insights that can transform your machining efficiency and product quality.

Explore further to discover what makes a coolant truly the best for your CNC machines.

Discover the Top Options to Keep Your CNC Operations Running Smoothly

| Image | Product | Price |

|---|---|---|

Pick 1  | Metal Cutting Oil Cutting Fluid for Machine Shops | Fusion | Check Price |

Pick 2  | Premium Synthetic Machining Coolant – 128 FL. OZ. (1 Gallon) | Check Price |

Pick 3  | Premium Soluble Machining Fluid – 128 FL. OZ. (1 Gallon) | Check Price |

1. Metal Cutting Oil Cutting Fluid for Machine Shops | Fusion

Discover the ultimate solution for precision and performance in your machining tasks with Fusion’s Metal Cutting Oil Cutting Fluid. Designed specifically for CNC machines and a variety of metalworking applications, this coolant stands out with its exceptional lubricating properties and advanced formulation, promoting smoother operations and longer tool life.

Fusion Cool 2240 is a semi-synthetic metal cutting fluid that excels in grinding, milling, threading, and more. Its ingenious water-soluble formulation ensures optimal cooling and lubrication across a diverse range of tools such as bandsaws and drill bits. Mix at 5-10% coolant with 90-95% water to unleash its full potential.

Mix at 5-10% coolant with 90-95% water to unleash its full potential.

Pros

- Versatile application for multiple metalworking tasks, enhancing overall efficiency.

- Low-odor and low-mist formula for a healthier work environment.

- Exceptional sump life reduces the frequency of maintenance and fluid replacement.

Cons

- Requires proper dilution to achieve optimal performance, which may not be convenient for all users.

Fusion Cool 2240 is not just a coolant but a vital upgrade for your machining operations, ensuring cleaner and more efficient workspaces. Elevate your machining precision today with the best coolant for CNC machines and see the difference in performance.

2. Premium Synthetic Machining Coolant – 128 FL. OZ. (1 Gallon)

Revolutionize your CNC machining experience with the Premium Synthetic Machining Coolant. Designed for durability and maximum efficiency, this coolant is a must-have for any serious machinist looking for the best coolant for CNC machines. Achieve excellent tool life and machine protection with ease.

Achieve excellent tool life and machine protection with ease.

Offering an extended coolant cycle, this synthetic formula resists odors and provides superior tramp oil rejection. Corrosion-resistant and made with industrial strength, it’s suitable for multi-metal machining and grinding applications, ensuring exceptional performance on every project.

Pros

- Extended coolant cycle for longer machine usage.

- Outstanding protection against tool and sump corrosion.

- Low odor formula enhances operator comfort during use.

Cons

- Some users may find the price slightly higher compared to conventional coolants.

Investing in the Premium Synthetic Machining Coolant enhances productivity and reduces downtime while giving you peace of mind with its industrial-strength formulation. Experience the difference and elevate the performance of your CNC machines with a product that stands out in the market.

3. Premium Soluble Machining Fluid – 128 FL. OZ. (1 Gallon)

Elevate your machining operations with the Premium Soluble Machining Fluid, designed specifically for CNC machines. Its industrial-strength formula ensures optimal cutting efficiency while maintaining a clean working environment.

This machining fluid excels in solubility with both hard and soft water, ensuring versatile use across various environments. The light viscosity base oils play a crucial role in reducing residues, promoting a cleaner machine.

Pros

- Outstanding solubility in varying water types enhances usability.

- Non-chlorinated composition promotes a safer working environment.

- Light viscosity aids in maintaining a cleaner machine, improving overall operational longevity.

Cons

- Occasional scent may be noticeable during prolonged use.

Invest in the Premium Soluble Machining Fluid for unrivaled performance in CNC operations, maximizing blade life and ensuring a clean machining environment. With its proven results, it’s an essential component for any machinist looking to optimize efficiency and reliability.

4. Mist Coolant for Metal Cutting Applications | Fusion Cool 2255

Unlock superior performance in metal cutting with the Fusion Cool 2255 Mist Coolant, designed specifically for CNC machines and tough machining environments. This high-performance coolant enhances tool longevity and efficiency while supporting a range of industrial applications.

Crafted for use in challenging conditions, Fusion Cool 2255 offers exceptional lubricity that caters to both abrasive materials and high-pressure tools. Its biocide formulation ensures extended sump life and effective tramp oil rejection, making it a leading choice for CNC plasma tables, milling, and various cutting operations.

Pros

- Superior lubrication for enhanced tool longevity.

- Effective in a variety of applications, from CNC machining to bandsaw work.

- Formulated with biocides for prolonged sump life and corrosion resistance.

Cons

- May require careful handling to maximize efficiency.

Experience the difference with Fusion Cool 2255 Mist Coolant, the best coolant for CNC machines that optimizes your metalworking operations and maximizes productivity. Elevate your machining processes today for improved performance and efficiency.

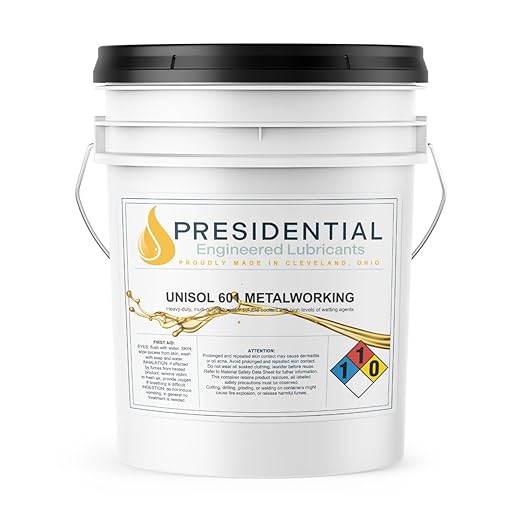

5. Presidential Unisol 601 Metalworking – Heavy Duty & Water Soluble

The Presidential Unisol 601 Metalworking Fluid stands out as the best coolant for CNC machines, offering exceptional performance with its multi-purpose, water-soluble formula. Designed for demanding machining applications, it ensures optimal lubrication and efficiency, making it an indispensable resource for professionals in the metalworking industry.

This heavy-duty coolant contains advanced EP and lubricity additives, enhancing machinability while protecting against wear and corrosion. Its versatile application ranges from cutting oil and machining to drilling and grinding, all while maintaining a stable emulsion with low foam. With a general mixing ratio of 10 to 1, it provides customized viscosity control tailored to your needs.

Pros

- Low foam formulation promotes cleaner operation, reducing maintenance.

- Contains corrosion protection and biocide, ensuring longer tool life.

- Stable emulsion with hard water stability for variable water conditions.

Cons

- Some users might find the initial dilution process complicated.

Overall, Presidential Unisol 601 Metalworking Fluid delivers performance and reliability, making it a smart investment for any machining operation. Experience the difference it makes in productivity and tool longevity today!

6. Plasma Cut – Green Coolant – Table and CNC Cutting

Unlock the full potential of your CNC cutting machines with the Plasma Cut – Green Coolant. Specially formulated for optimal performance, this coolant ensures precision and longevity in your operations, making it the best coolant for CNC machines on the market today. Experience enhanced cut quality and reduced maintenance time effortlessly.

Engineered with superior rust inhibition to protect your metal parts, the Plasma Cut coolant features advanced slag release agents that significantly enhance clean-up efforts. With the ability to prevent metal warping and improve cut quality, this coolant effectively meets the demanding needs of industrial applications.

Pros

- Exceptional rust prevention that stops “flash rust” on finished metal parts.

- Advanced slag release agents for effortless maintenance and less splashing during use.

- Helps maintain a cooler work environment, enhancing precision in cuts while reducing warping.

Cons

- Requires specific handling instructions for optimal performance in industrial settings.

In conclusion, the Plasma Cut – Green Coolant is an outstanding investment for any CNC machine operator seeking improved cut quality and machine longevity. Its unique formulation and performance advantages make it a superior choice compared to standard coolants available in the market.

7. Ade Advanced Optics RHB-10ATC-1 0-10% ATC BRIX Refractometer 4 Sap,

The Ade Advanced Optics RHB-10ATC-1 Refractometer stands out as an essential tool for anyone involved in testing the concentration of coolants, particularly in CNC machining and raw maple sap. Its reliable operation and sturdy construction ensure accurate results that professionals demand.

This refractometer features automatic temperature compensation, delivering precise measurements with an accuracy of +/- 10 percent Brix.

Crafted from durable aluminum, it is designed for longevity and ease of use. Included with your purchase are a pipette for fluid application, a mini screwdriver for adjustments, and a user guide for seamless operation.

Pros

- Automatic temperature compensation ensures accurate readings across varying conditions.

- Sturdy aluminum construction offers enhanced durability compared to plastic alternatives.

- Lightweight design at just 0.7 ounces makes it portable for on-the-go testing.

Cons

- The simplicity of design may lack advanced features found in higher-end models.

The Ade Advanced Optics RHB-10ATC-1 is not just a refractometer; it’s an indispensable tool for ensuring optimal coolant performance. Its affordability and reliability make it a smart choice for both professionals and hobbyists in the CNC machining space. Upgrade your testing methods today!

Upgrade your testing methods today!

8. Kool Mist #77 Concentrated Coolant – Container Size: 1 Gallon

Discover the Kool Mist #77 Concentrated Coolant, your essential partner for optimal performance in CNC machining. Specially designed for any metal or alloy, this coolant not only enhances machining effectiveness but also prioritizes safety for users and the environment.

Formulated to dissolve in water for a clear solution, this coolant ensures smooth operation across various machining processes while keeping your machinery in peak condition. Packaged in a 1-gallon container, its robust design offers both convenience and value, making it an ideal choice for both professionals and enthusiasts.

Pros

- Environmentally friendly and safe for all users

- Versatile, suitable for machining any metal or alloy

- Dissolves easily in water, ensuring high compatibility

Cons

- Some users may find it slightly more expensive compared to generic coolants

Upgrade your CNC machining experience with Kool Mist #77 Concentrated Coolant. It not only safeguards equipment but also enhances machining quality, proving to be a valuable investment for anyone serious about their craft.

9. Mist Coolant for Metal Cutting Applications | Fusion Cool 2255

Experience superior machining performance with the Mist Coolant for Metal Cutting Applications, Fusion Cool Designed specifically for CNC machines and metal cutting operations, this coolant enhances tool life and delivers exceptional lubricity, making it the go-to choice for demanding machining environments.

Formulated to excel in both general-purpose and tough conditions, this product is ideal for various applications, including CNC plasma tables, milling, and drilling. The blend of biocides protects against tool wear and extends sump life by repelling tramp oil, ensuring a clean and efficient machining experience with dilutions as low as 3%.

Pros

- Provides excellent lubrication under high pressure, ensuring tool protection and longevity.

- Multi-functional usage, suitable for various cutting applications including grinding and turning.

- Contains biocides to inhibit corrosion and effectively manage tramp oil build-up.

Cons

- Some users may prefer a more concentrated coolant for specific applications.

In conclusion, Fusion Cool 2255 Mist Coolant stands out as one of the best coolants for CNC machines, ensuring reliable performance and protection in various metal cutting tasks. Elevate your machining accuracy and tool life with this exceptional coolant solution.

10. OriGlam Mist Coolant Lubrication Spray System for Metal Cutting Engraving

Elevate your machining processes with the OriGlam Mist Coolant Lubrication Spray System, designed for metal cutting and engraving. This efficient spray ensures optimal cooling while providing effective lubrication, making it an essential tool for precision work in any industrial setting.

Engineered with a fully sealed structure, the OriGlam Mist Coolant prevents air leakage, enhancing safety during operation. Its adjustable air flow and mist volume allows for customizable use depending on the task at hand.

Quick and easy to implement, this system enhances cutting speeds while reducing tool wear and minimizing cleanup time.

Pros

- Fully sealed design eliminates air leakage, ensuring efficiency and safety.

- Adjustable air flow and mist volume for tailored application to various tasks.

- Reduces machining time, saving costs while extending tool lifespan.

Cons

- The unit may require some initial setup for optimal performance.

Investing in the OriGlam Mist Coolant Lubrication Spray System provides significant efficiency and productivity boosts in metalworking tasks. With its value-driven design and performance enhancements, this coolant system stands out as one of the best coolant options for CNC machines available on the market today.

Top Coolants for CNC Machines: Ultimate Buying Guide

Maintenance requirements

When selecting the right coolant for CNC machines, it’s essential to understand various factors that ensure optimal performance and longevity for your equipment. Look for products that offer effective contaminant control, which is crucial for maintaining clean cutting tools and preventing wear.

Routine cleaning and disposal of the coolant should also be considered, as a clean working environment enhances efficiency and prolongs the life of your machine. Additionally, take note of the fluid replacement intervals recommended by manufacturers; knowing how often you need to change the coolant can help you plan maintenance schedules effectively. By considering these key features and recommended practices, you will be better equipped to choose a coolant that meets your operational needs while safeguarding your machinery against unnecessary wear and tear.

Cooling efficiency

Choosing the right coolant for CNC machines involves understanding several key features that ensure optimal performance and longevity of your equipment. One important aspect to consider is heat transfer capabilities, as effective coolants must efficiently dissipate heat generated during machining processes. This can prevent overheating and improve the overall lifespan of your tools and machines.

Additionally, pay attention to the viscosity and flow characteristics of the coolant, as these factors influence how well the coolant circulates within the system. A coolant with appropriate viscosity will maintain a consistent flow, ensuring that all areas of the machine receive adequate lubrication and cooling.

Moreover, examining the boiling and freezing points of the coolant is essential; you want a product that remains stable under extreme temperature fluctuations, preventing evaporation or solidification that could lead to machine damage. When making your selection, consider your specific machining applications and environmental conditions to ensure you choose a coolant that meets your operational needs.

Compatibility with cnc machines

When selecting a coolant, understanding manufacturer recommendations is crucial for maintaining the integrity of your CNC machines. Different coolants have varying compositions, which should align with the materials your machines are constructed from. For example, certain metals may react adversely with specific coolant types, leading to corrosion or degradation of machine components.

For example, certain metals may react adversely with specific coolant types, leading to corrosion or degradation of machine components. The material composition of your CNC machine’s elements plays a significant role in determining the optimal coolant to use, ensuring both protection and efficiency. A good coolant not only helps lubricate the cutting tools but also contributes to efficient heat dissipation, ultimately enhancing machine performance and longevity.

Additionally, keep in mind that using an inappropriate coolant can lead to increased wear and tear, resulting in costly repairs or downtime. It’s advisable to conduct thorough research on the specific requirements of your machines and consult with manufacturers to make an informed decision on the types of coolants that will suit your applications best.

Cost considerations

When considering a coolant for CNC machines, it is essential to recognize the critical features that can impact performance and efficiency. Look for a coolant that offers excellent thermal stability, which ensures consistent cooling during machining processes, preventing overheating and prolonging the life of both the tool and the workpiece.

It is also advantageous to select a coolant that provides adequate anti-corrosion properties, as CNC machines often work with various metals that can be prone to oxidation. Usage scenarios vary widely, from milling and turning to grinding operations, so ensure the coolant is suitable for your specific applications to achieve optimal results.

As for purchasing tips, pay attention to the price per gallon or liter, as this can vary significantly between different coolant types. By evaluating long-term cost implications, such as how often you’ll need to change the coolant and how it performs, you can make a more informed choice. Exploring bulk purchasing options can also lead to significant savings, especially if your machining operations require substantial quantities of coolant regularly.

Exploring bulk purchasing options can also lead to significant savings, especially if your machining operations require substantial quantities of coolant regularly. Always consider reading reviews and seeking recommendations to find a formulation that meets your operational needs effectively.

Types of coolants

When selecting a coolant for CNC machines, it’s essential to consider different types that suit various machining processes. Watersoluble coolants are popular due to their versatility and effective cooling abilities, allowing for easier cleanup and better lubrication during machining operations.

Oilbased coolants, on the other hand, provide excellent lubrication and are typically favored for heavy-duty machining tasks, although they can be messier and require more extensive maintenance. They are great for operations that generate high levels of heat.

Lastly, synthetic coolants offer an alternative that combines the advantages of both types, providing excellent thermal stability and lubrication without the oil content, making them suitable for environmentally conscious users or those requiring a non-flammable solution. When purchasing a coolant, it’s wise to consider the specific requirements of your machining process, including the materials involved, the type of cutting tools used, and any regulatory or safety standards that apply.

Taking the time to understand the properties of each coolant type will greatly enhance the performance of your CNC machine and improve the quality of your finished products.

Environmental and health impact

When considering coolants for CNC machines, it’s crucial to explore various options that not only enhance performance but also prioritize safety and environmental responsibility. Many manufacturers now offer biodegradable alternatives that effectively reduce the ecological footprint without compromising cooling efficiency.

Furthermore, staying informed about regulations and compliance considerations in your region can help you make a responsible choice, ensuring you select a coolant that aligns with industry standards and environmental guidelines. By focusing on these key features and considerations, you can select a coolant that meets both your operational needs and your commitment to sustainability.

Frequently Asked Questions

What Are The Benefits Of Using Biodegradable Coolants In Cnc Machining Applications?

Biodegradable coolants in CNC machining applications offer environmental benefits by reducing pollution and minimizing the ecological impact of manufacturing waste. Additionally, they can enhance worker safety by being less toxic and irritant compared to traditional petroleum-based coolants.

What Are The Common Signs Of Coolant Degradation, And How Can It Affect Cnc Machine Operations?

Common signs of coolant degradation include discoloration, an unpleasant odor, and the presence of sludge or particulates. Degraded coolant can lead to increased heat, reduced lubrication, and potential damage to the CNC machine components, ultimately affecting machining accuracy and operational efficiency.

How Often Should Coolant Be Changed Or Filtered In Cnc Machines To Maintain Optimal Performance?

Coolant in CNC machines should typically be changed or filtered every 2 to 6 months, depending on usage and contamination levels. Regular checks and maintenance can help ensure optimal performance and extend the life of both the coolant and the machine.

How Do Different Types Of Coolant (Oil-Based Vs. Water-Based) Impact Cnc Machining Performance?

Oil-based coolants generally provide better lubrication and can enhance tool life, making them suitable for high-heat operations, while water-based coolants offer superior cooling capabilities and are typically less expensive, but may lead to rust or corrosion if not managed properly. The choice between them depends on the specific machining requirements and materials being processed.

What Are The Key Properties To Look For In The Best Coolant For Cnc Machines?

When selecting the best coolant for CNC machines, key properties to consider include thermal stability to prevent overheating, lubricity to reduce friction and wear, and corrosion resistance to protect machine components. Additionally, the coolant should have a suitable viscosity for effective flow and delivery throughout the system.

Conclusion

In summary, selecting the best coolant for CNC machines is crucial for optimizing performance and extending tool life. Consider factors such as thermal conductivity, viscosity, and compatibility with materials.

Popular options include water-soluble oils and synthetic coolants, each offering unique benefits. Invest in high-quality coolant to enhance machining efficiency and ensure precision in your operations. Choose wisely for superior results!